In emulsion

polymerization, a dispersion of polymer in aqueous phase (latex) is obtained.

The solids content is usually between 40-65 %w. These polymers are broadly used

in paints, adhesives, rubbers, binders and additives for the paper and textile

industry. The development of reliable mathematical models for emulsion

polymerization requires a high level of understanding of the phenomena taking

place in the reactor. In this article, we offer a brief overview of the basic

steps in batch emulsion polymerization and we discuss the kinetics of the

process. Common monomers employed in this polymerization are styrene, methyl

methacrylate or vinyl acetate.

The monomer

feed is dispersed using water emulsifiers

or surfactants. These are typically

molecules like Sodium Lauryl Sulfate with a non-polar tail and a water soluble

end which stabilize the monomer droplets

in the aqueous phase. The excess of surfactant forms micelles which are swollen with monomer, as it is described in the

following figure:

Polymerization

is started by means of a water soluble initiator (tert-butyl hydroperoxide,

potassium persulfate). Thus radicals are formed in the aqueous phase from the

small amount of monomer dissolved. When the oligoradical chain has grown to a

certain extent, it becomes hydrophobic and enters one of the micelles (the

entry to the monomer droplets is unlikely because of the low total surface area

that these represent). This is called heterogeneous nucleation and as a result

a polymer particle is formed. If the

oligoradical does not enter a micelle, it will continue growing until it

precipitates absorbing emulsifier (homogeneous nucleation). This situation is

described in the following figure:

In this

stage there is a coexistence of monomer droplets, monomer swollen micelles and polymer

particles in the reactor. Monomer is consumed inside the polymer particles

according to the free radical polymerization mechanisms. The monomer consumed

is replaced by monomer that diffuses from the droplets. The micelles in the

system decrease because they are converted to polymer particles or they are

destroyed to provide enough surfactant to the growing polymer particles. When

all the micelles disappear (5-10% of monomer conversion), the nucleation

interval has come to an end:

At this

stage, the system consists of polymer particles and monomer droplets. Given

that the mass transfer rate for monomers with higher water solubility than

styrene is higher than the polymerization rate, the monomer concentration in

the polymer particles reaches a maximum and constant value. When solubility is

too low, this stage can be diffusionally limited.

As monomer

diffuses from droplets to particles, these grow until the monomer droplets

disappear. At this point the system is exclusively composed of polymer particles.

The monomer conversion at which this takes place highly depends on the capacity

of the particles to be swollen with monomer (40% for styrene, 15% for vinyl

acetate). In this new interval the monomer concentration is the particles

decreases until polymerization is completed. Finally, polymer particles in a

latex of size varying from 80-300nm are obtained:

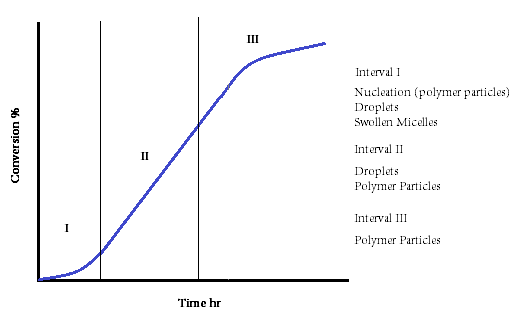

These

stages are summarized in the following conversion-time figure:

The rate of

polymerization in the polymer particles is similar to the bulk polymerizations,

where kp is the propagation constant [m3 mol-1

s-1], [M]p is the monomer concentration in the polymer

particles, n is the average

number of radicals per particle, Np the number of polymer particles

and NA the Avogadro’s number:

Since in

emulsion polymerization the radicals are distributed among the particles, the

overall radical concentration is much higher than in bulk polymerization,

resulting in a higher polymerization rate. Radicals have a longer life time leading

to higher molecular weights, and are not terminated until another radical

enters the particle, which is less probable if there are more polymer particles

in the system. Therefore, the polymerization rate and the molecular weight can

be increased simultaneously by increasing the number of particles. This is an

advantageous characteristic of emulsion polymerization that could not be

attained in bulk or solution polymerization.

Carlos

Arnaiz del Pozo